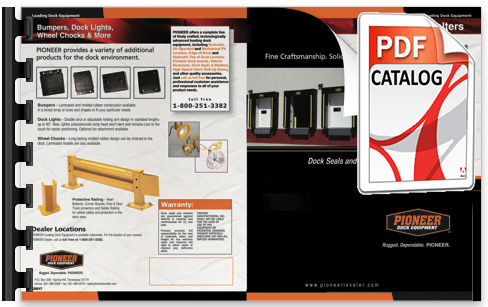

LOADING DOCK EQUIPMENT

Pioneer Dock Equipment manufactures and distributes a wide range of loading dock equipment. Pioneer is centrally located in Spring Hill, Tennessee, and sells through a national network of dealers.

Pioneer Dock Equipment has been one of the leading manufacturers of quality loading dock equipment for more than 40 years. As such, our products are offered by many material handling, industrial door and forklift distributors across the US, in Mexico and Canada.

Dock Levelers

SMART+™ HDH SERIES

55,000 lb. Minimum yield steel tread plate on the deck and lip

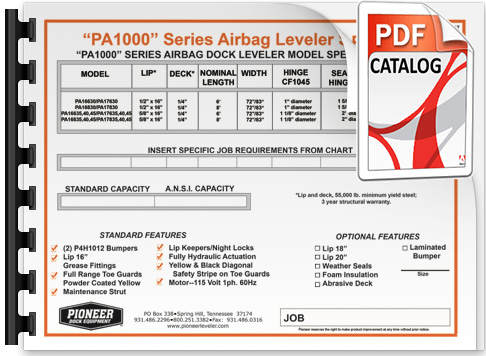

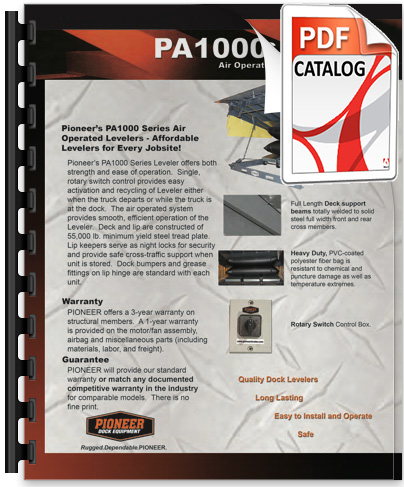

Heavy Duty, PVC-coated polyester fiber bag is resistant to chemical and puncture damage as well as temperature extremes.

All operations are controlled from a pre-wired wall mounted control box.

Full range toe guards powder coated safety yellow

Grease fittings on lip hinge

Lip will yield under impact

4 1/2” laminated bumpers, two per dock leveler

16″ Lip projection – 12″ beyond bumpers

Cross traffic support and night lock security to be provided by lip stored in lip keepers

Standard maintenance strut

Standard dynamic capacities available

Operating range of 12″ above to 12″ below deck

Leveler may be recycled with truck in position

Safety legs automatically provide multiple below dock safety points

3 year warranty on all structural members

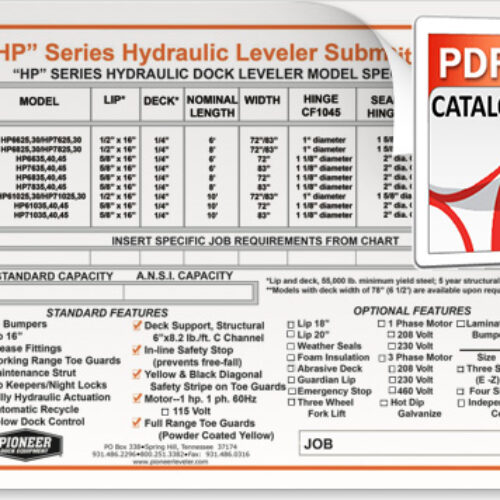

SMART+™ HP SERIES

55,000 pound minimum yield steel tread plate

Structural “C” channel support beams

25,000 – 45,000 lb. capacities

Automatic lip extension

Automatic return to stored position when truck leaves

In-line safety stop prevents sudden fall of deck

Full operating range toe guards and grease fittings on lip hinge

Heavy duty main and lip cylinder

Molded bumpers protect the dock face and leveler from truck impact damage

5 year warranty on all structural members and cylinders

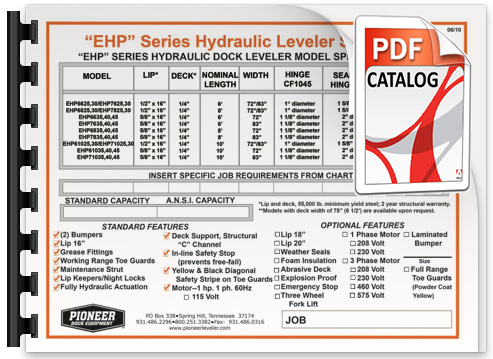

EHP SERIES

SMART+TM HDH Series

The SMART+TM line of levelers combines cutting-edge technology with durable, dependable, fully hydraulic operation. The SMART+TM HP and HDH levelers feature HMI – Human Machine Interface – control panels for simpler, more intuitive operation as well as our reliable solid steel structural “C” channel design and solid sate proximity sensors to control deck and lip functions. Available in Dynamic Capacities up to 80,000 lb.

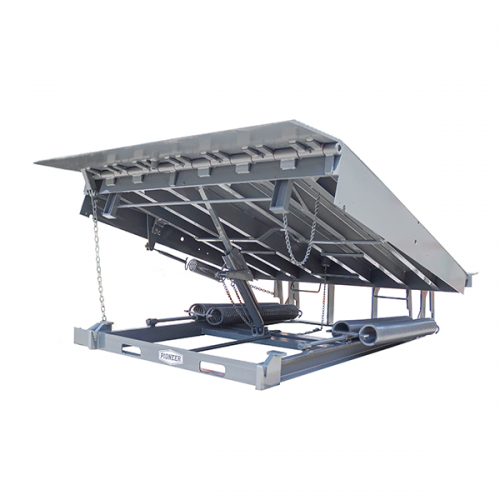

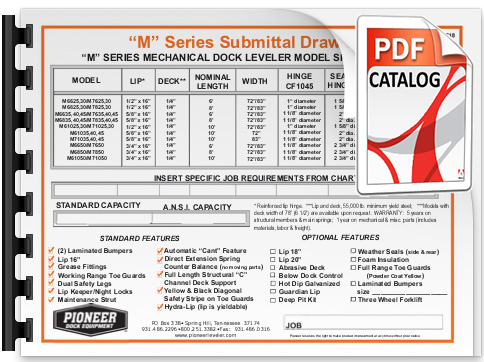

M SERIES

55,000 pound minimum yield steel trad plate

Structural “C” channel deck support beams

Dock bumpers and grease fittings on lip hinges are standard

Provides 18” and 20” lip options

Conveniently located pull chain provides easy activation of the deck and lip

Standard working range toe guards and grease fittings on lip hinge

Safety legs automatically provide multiple below dock safety points

Molded bumpers protect the dock face and leveler from truck impact damage

5 year warranty on structural members

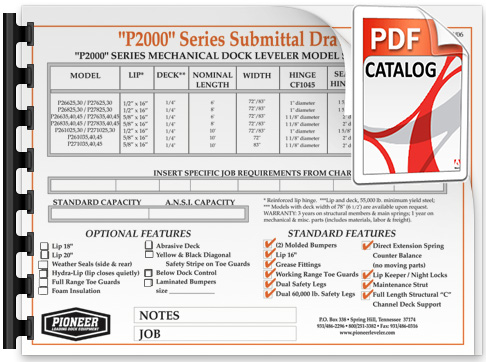

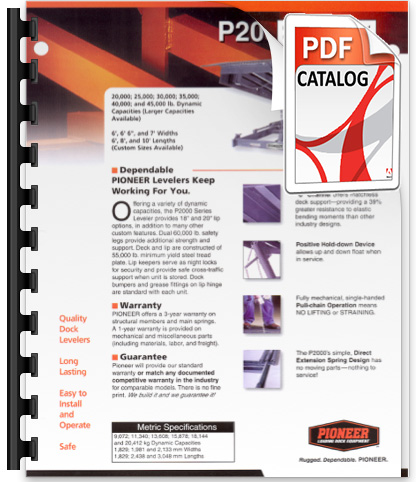

P2000 SERIES

55,000 pound minimum yield steel tread plate

Structural “C” channel deck support beams

Dock bumpers and grease fittings on lip hinges are standard

Conveniently located pull chain provides easy activation of the deck and lip

Direct extension spring provides easy walk down; no moving parts to wear out

Standard working range toe guards and grease fittings on lip hinge

Safety legs automatically provide multiple below dock safety points

Molded bumpers protect the dock face and leveler from truck impact damage

3 year warranty on all structural members and main spring (P2000)

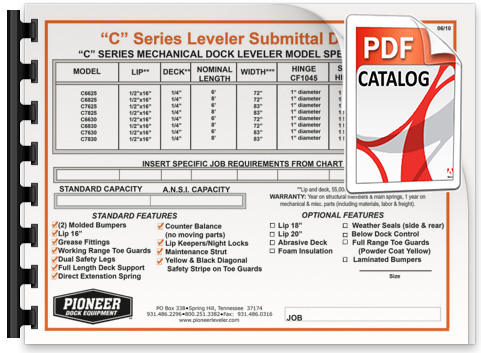

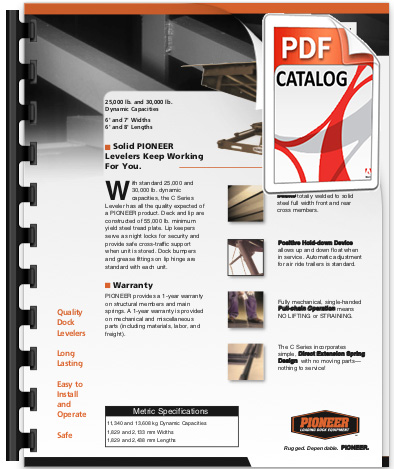

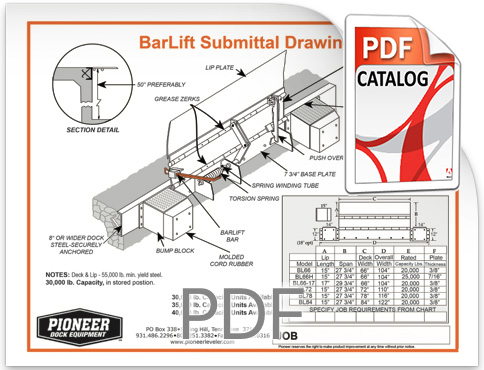

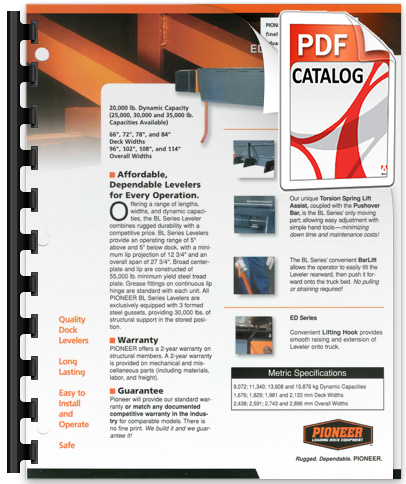

C SERIES

55,000 pound minimum yield steel tread plate

Full length deck support beams fully welded to full width header plate

Positive Hold Down device compensates for vertical float of trailer

Conveniently located pull chain provides easy activation of the deck and lip

Direct extension spring provides easy walk down; no moving parts to wear out

Standard working range toe guards and grease fittings on lip hinge

Safety legs automatically provide multiple below dock safety points

Molded bumpers protect the dock face and leveler from truck impact damage

Fixed rear hinge.

1 year warranty on all structural members and main spring

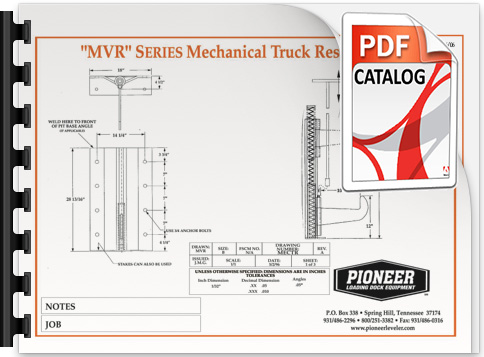

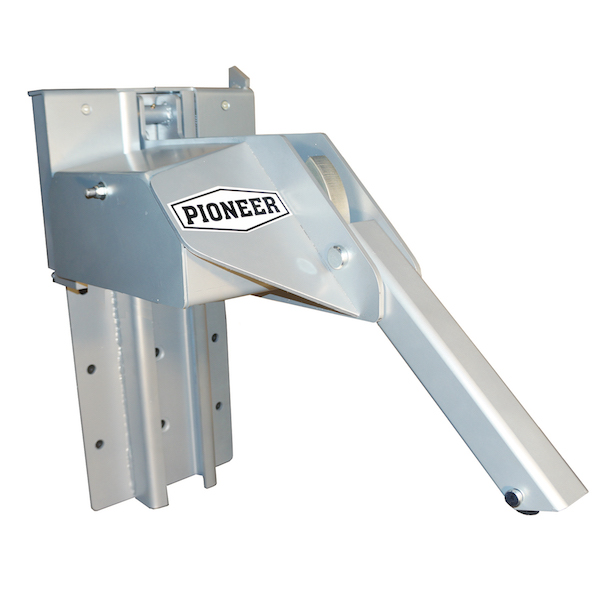

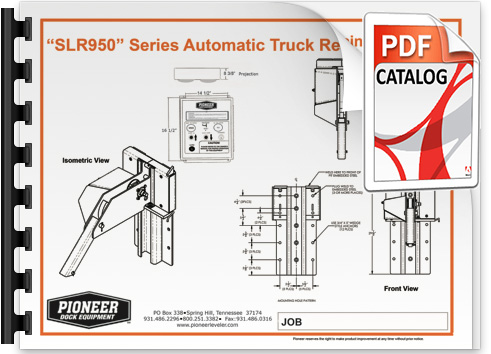

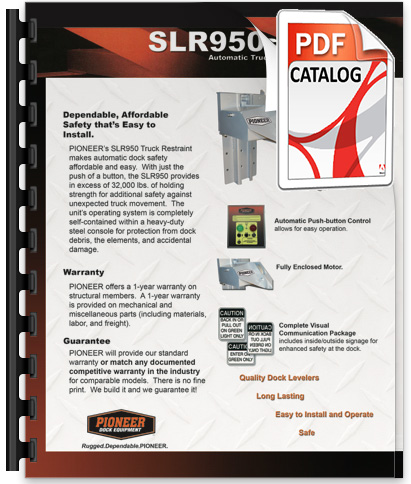

TRUCK RESTRAINT EQUIPMENT

EVR 650 SERIES

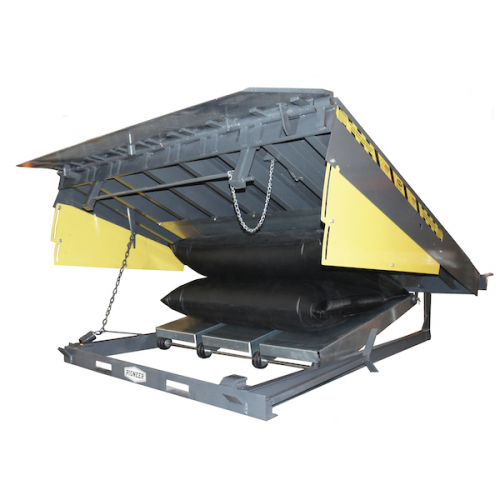

55,000 lb. Minimum yield steel tread plate on the deck and lip

Heavy Duty, PVC-coated polyester fiber bag is resistant to chemical and puncture damage as well as temperature extremes.

All operations are controlled from a pre-wired wall mounted control box.

Full range toe guards powder coated safety yellow

Grease fittings on lip hinge

Lip will yield under impact

4 1/2” laminated bumpers, two per dock leveler

16″ Lip projection – 12″ beyond bumpers

Cross traffic support and night lock security to be provided by lip stored in lip keepers

Standard maintenance strut

Standard dynamic capacities available

Operating range of 12″ above to 12″ below deck

Leveler may be recycled with truck in position

Safety legs automatically provide multiple below dock safety points

3 year warranty on all structural members

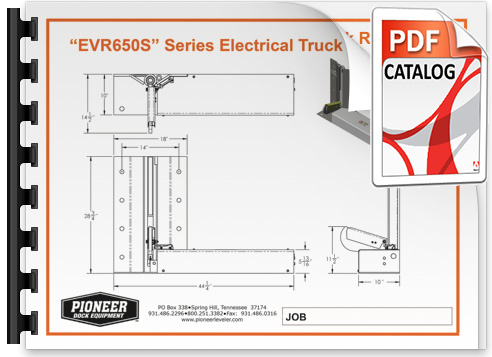

EVR 650S SERIES

The unique “Hook Guard” senses the fully captured R.I.G. and automatically changes the inside and outside lights.This design provides redundant positive hook feedback, supported by programmed logic, in the event of a bent or Missing R.I.G. or improperly located trailer.

Low profile

12″ to 30″ operating range

Restraining force of over 50,000 lbs.

Fully enclosed, .25hp motor, 1 ph., 115 volts

Automatic push-button control for easy operation

.25hp motor, 1 ph., 115 volts

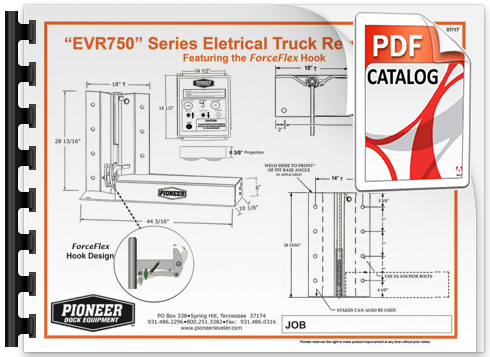

EVR 750 SERIES

ForceFlex hook designs offers superior holding strength yet will allow the truck to depart with the release button is pressed.

ForceFlex hook only releases when the dock attendant presses the release button.

12” to 30” operating range

Restraining force of over 37,000 lbs.

Fully enclosed, .25hp motor, 1 ps., 115 volts

Automatic push-button control for easy operation

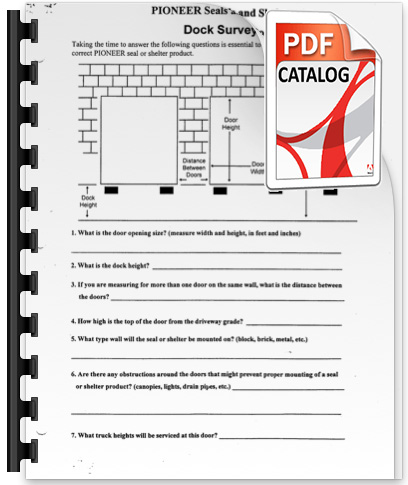

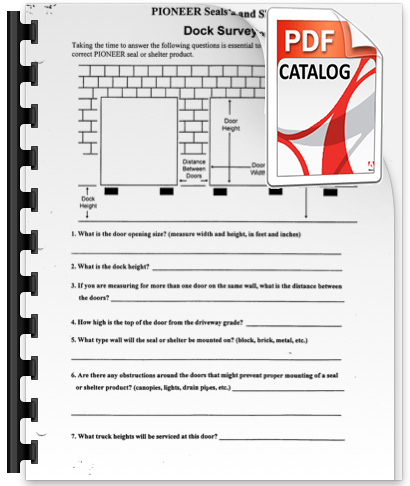

Seals and Shelters

DOCK SEALS

Weather tight enclosure for maximum energy savings

100% lock-stitched seams-double stitched on wear shingle models

Assorted colors

4″ full length yellow guide strap standard

Head curtain models available with or without foam

Counterbalanced adjustable head pad available

Metal hoods

All models use highest grade materials available

Fabric weight protection from 40 to 140 oz.

Pressure treated wood backing – steel backing optional

DOCK SHELTERS

Raked cut header on all rigid wood frame models prevents water from standing on top

Heavy duty structural channel support/protective bumpers with rigid type units

Overlapping weather shingles on head curtains

Side and head curtain wiper action allows full access to rear of truck

Face curtains on rigid type include scotch ply fiberglass stays and yellow guide stripes

Rigid frame models have 6oz. translucent white fiberglass top cover

Side covers translucent 28 oz. P.V.C. base fabric or 6 oz. translucent fiberglass

DURA SEAL

PX25 (high tear) base material

LTA material (our high tear PX420)

Side pad wedge standard as dictated by opening width

Head curtain style available with slits on each side (optional pull cord available)

20″ wide, PX420 wear pleats on the corners of the head pad. On head curtain models the wear pleats are the same width as the side pad.

PX420 inside wear face on bottom 48″ of each side pad

Three Year Warranty